Gartner research tells us that supply chain leaders perceive technology primarily as a competitive advantage. However, it also says “80% of organisations favour a cautious approach when it comes to adopting new supply chain applications and technologies”.

So why’s there such a disconnect between technological aspirations and implementation?

It’s because legacy supply chain platforms weren’t designed or implemented for a world where a new technological innovation arrives twice quarterly.

Just keeping up with half the things on Gartner’s “hype cycle” is hard enough, let alone actually implementing things like AI, IoT, robotics, or descriptive analytics into a supply chain.

On these legacy platforms, where integration was only ever an afterthought, adapting to new technology is so much harder.

It’s not all doom and gloom. Take Foodstuffs’ promising eXchange project – designed to flex with any future advancements.

Why Foodstuffs’ eXchange is marching onwards

Foodstuffs is the country’s biggest grocery retailer and distributor, which includes New World, PAK’nSAVE, and Four Square.

The proudly Kiwi-owned and locally-operated business employs more than 30,000 people nationwide, works with over three thousand suppliers, and has over 200k customer transactions running through its stores every day.

But its supplier interchange (aka eXchange) was ageing in such a fast moving environment.

Integrations with Foodstuffs’ existing system – based on BizTalk integration, an SQL Server, and a variety of web applications – had become challenging for a growing list of popular vendors. This was slowing Foodstuffs’ capacity to move groceries from suppliers to the store shelf.

To compound the issue, Microsoft’s support of BizTalk was ending, so Foodstuffs was working against the clock.

And that’s a huge concern for a system that handles more than 73 million transactions annually, interfacing with over 3000 suppliers to process invoices and PO’s.

But an overhaul project was risky.

Instead of just rebooting their rapidly declining eXchange, Foodstuffs seized the opportunity to evolve the platform into something fit for future developments.

“I wanted our new eXchange to evolve from handling supplier invoices and purchase orders to serving as an eCommerce platform able to flex with any kind of integration work customers and suppliers might need.”

- Chris Monkton, Purchasing Process Owner, Foodstuffs North Island

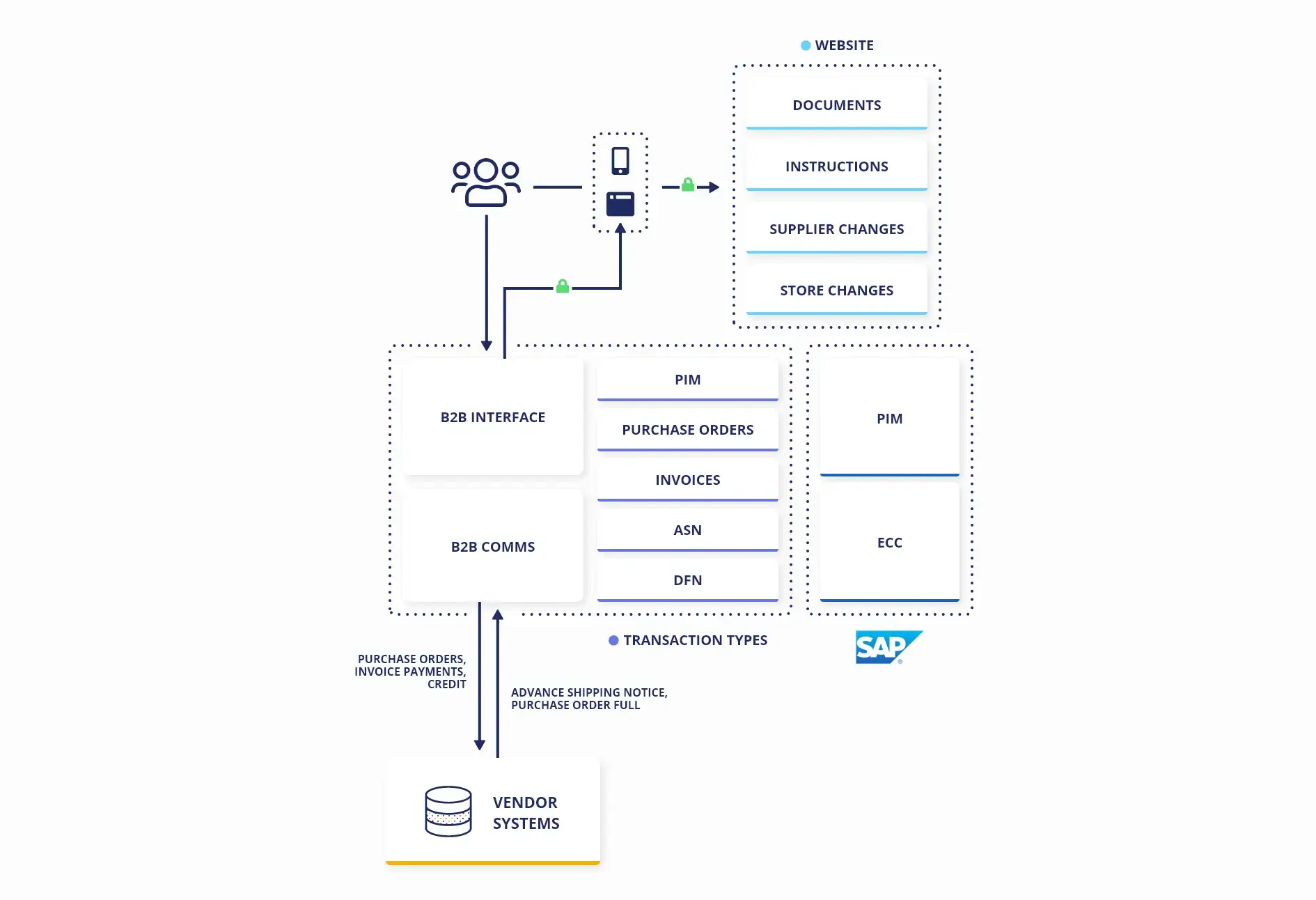

So Sandfield’s developer team set about implementing a new, highly integrated eXchange portal on a flexible architecture that specifically aligned with Foodstuffs’ eCommerce ecosystem vision.

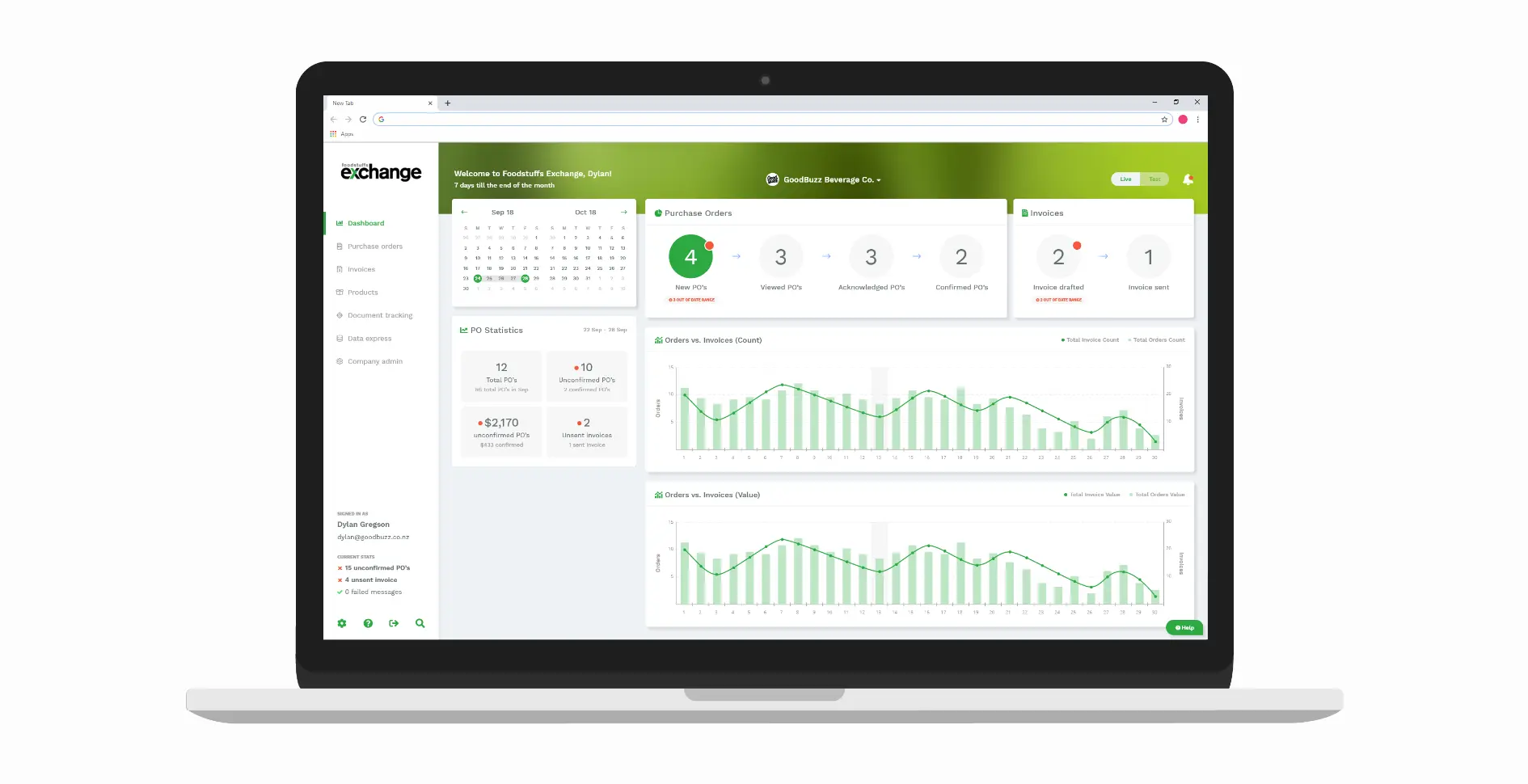

Atop flexible foundations, Foodstuffs’ new eXchange portal delivered three core functions into one user-friendly portal:

A Supplier-centric Portal – By integrating data from two other Foodstuffs systems (Data eXpress and SRM (supplier relationship management), everything from purchasing, invoicing, and delivery forecast notifications, through to advance shipment notices and supplier communication, are now managed in one place, with one login. Something that historically required three separate logins.

Moreover, the new portal delivers visibility over transactions, interactive vendor EDI configurations, and trading party relationship maintenance.

EDI Integration – Primarily used for purchasing and invoicing transactions, this critical integration accounted for over 80% of Foodstuffs’ transactions. Crucially, it means one source of data and truth for the entire Foodstuffs team.

Transacting electronically also ramps up efficiency by removing manual data entry tasks that introduce errors and take valuable time away from building effective relationships.

Product Information Management (PIM) – Suppliers can now update product information, including composition, allergens, images, weight, size, and more. And for a company that receives product data from about 400 suppliers from the GS1 national product catalogue, the eXchange now integrates these data feeds which reduces supplier administration when adding a new product or modifying their range.

An eye on future flexibility

An eye on future flexibility

Because Sandfield manages oversight of the entire environment (integration experts Crossfire are a Sandfield Division), the platform is primed to evolve rapidly to meet Foodstuffs’ increasingly sophisticated future requirements.

In tech and in business, visibility is everything. The Sandfield team manages the entire eXchange tech stack, there are no third-party platforms providing unknown variables. This, coupled with adaptable foundations ensure cost-effectiveness and efficiency as Foodstuffs evolves. A flexible system means flexible operations.

“The end goal for the eXchange is a fully rounded eCommerce and supplier ecosystem. So no matter what businesses are dealing with us on -- PO’s, transactions, product ingredients -- we want a single environment where they can come to and do everything they need to do with us.”

Chris Monkton, Purchasing Process Owner, Foodstuffs North Island.

Phase 2 is already underway. The Foodstuffs and Sandfield teams are reducing operational costs and improving processes, including automating the claims and credit process, providing suppliers with self-service statement reconciliation, and providing an API for suppliers so they can integrate directly with their own systems.

"This will allow us to be nimbler and even more responsive to technological advancements, ensuring we remain well-placed to deliver the best trading experience with Foodstuffs."

- Ana Connor, Master Data Operations, Foodstuffs South Island

Is it working?

A busy Christmas season followed by the COVID lockdown put the new eXchange to the test immediately, processing more than 200,000 transactions daily. At times, the eXchange was processing 50,000+ messages per hour (usual trading periods see about 80,000 messages per day).

“Despite the rising volume of orders we processed during COVID lockdown, I have no complaints. I was really proud of that and the system. It’s the uptime that I really appreciate, the new eXchange now has effectively 99.99% uptime, that’s what matters for us. And on that 0.01% occasion it’s down, it’s very responsive to being fixed.”

- Chris Monkton, Purchasing Process Owner, Foodstuffs North Island

The in-built system flexibility has paid off bigtime. And it’s set Foodstuffs up to have more time to move faster on new developments to continue growing their business.

“The very orderly and smooth process enabled by the new eXchange means my role has been able to evolve. I can now focus on our supply chain strategy in Phase 2 rather than all the basics we were focusing on in Phase 1. I’ve been able to look deeper at the work Sandfield is doing with other clients and identify some of their clever developments to apply to Foodstuffs.”

- Chris Monkton, Purchasing Process Owner, Foodstuffs North Island