With companies generating more than two-thirds of the planet’s carbon dioxide (CO2) emissions, 90% of those produced in the supply chain, the pressure is now on businesses, globally, to not only be part of the solution but to also be more transparent with their emissions data.

This collective change is not only being driven by government policy and major environmental groups - consumers are also now demanding more transparency to determine which brands to engage with - or not.

But calculating a product’s entire carbon footprint is no mean feat and requires major collaboration from players right across a business’ supply chain.

One company leading the way in helping their clients achieve this is global logistics operator, Mainfreight, who is using tech to track and provide more visibility of emissions generated in transporting their client’s goods around the world.

Transport accounts for one-fifth of the total global carbon dioxide (CO2) emissions, with over half of that generated by the transport and logistics industry alone.

Mainfreight already knows the power of custom technology and its ability to be a game-changer for its business and customers, having developed and evolved a tailored supply chain management system, in partnership with Sandfield, over several decades.

Whilst a number of solutions already exist that estimate emissions used from various modes of transport within a supply chain, Mainfreight’s bold ambition was to extend its capabilities to provide customers with a more accurate, and detailed, view of the emissions generated in the movement of their freight.

Partnering with Sandfield, Mainfreight developed an integrated carbon emissions calculator that not only provides customers with more accurate emissions insights, but can also assist them in making better, more sustainable business decisions in the future.

Mainfreight’s emission mission

Mainfreight’s ambitious brief to Sandfield was to create a solution that pulled all global emissions data from its international shipment activities, with the long-term goal of providing one clear dashboard for customers.

While the company had already been calculating emissions from its own land transport fleet, the air and ocean legs were largely unknown entities given they were entirely run by third-party providers.

The solution needed to integrate into Mainfreight’s existing systems, accurately calculate emissions for each leg of a shipment, specific to the mode of transport, and seamlessly return the result back into Mainfreight’s management system to report back to clients. It also needed to have flexible foundations so that future opportunities to compare specific routes and help plot an optimal path (with the least amount of emissions) could be realised.

The carbon calculator

Sandfield’s solution for Mainfreight focused on creating a carbon calculator application that could grow in sophistication over time.

With limited information on emissions generated from each carrier, the first stage of the project involved creating a system that calculated emissions to a minimum standard recommended by the GLEC framework, a leading methodology for freight transport, using existing data.

The GLEC framework is essentially a meta-standard as it combines existing methods and algorithms for calculating logistics emissions. The key to Mainfreight’s success was to gather as much data as possible to feed into the framework, and then continue to build on that moving forward.

Sandfield created an API for Mainfreight’s international shipping system to allow full emissions reporting which lends itself to estimation and visualisation for its own reference and to also share with clients. In time, Mainfreight and its customers could then simulate potential emissions before freight is moved.

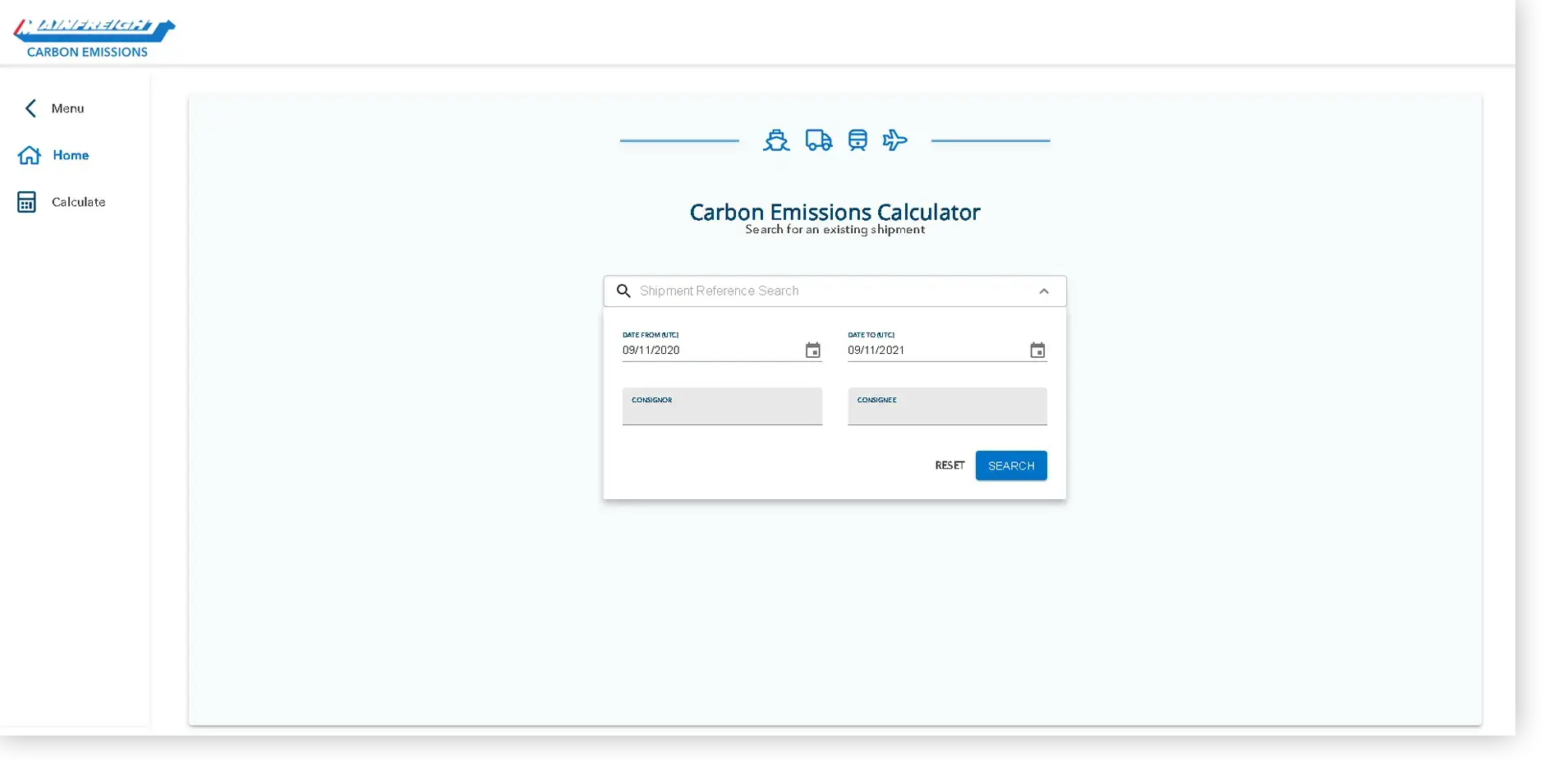

In order to create even more visibility and functionality, Sandfield also developed a user interface (UI) which provided Mainfreight with the ability to search different jobs to check the accuracy of the calculations. It also allows analysis of larger amounts of data to uncover more efficient routes for customers to help reduce emissions in the future.

Mainfreight’s carbon calculator homepage for searching CO2e across all available shipments.

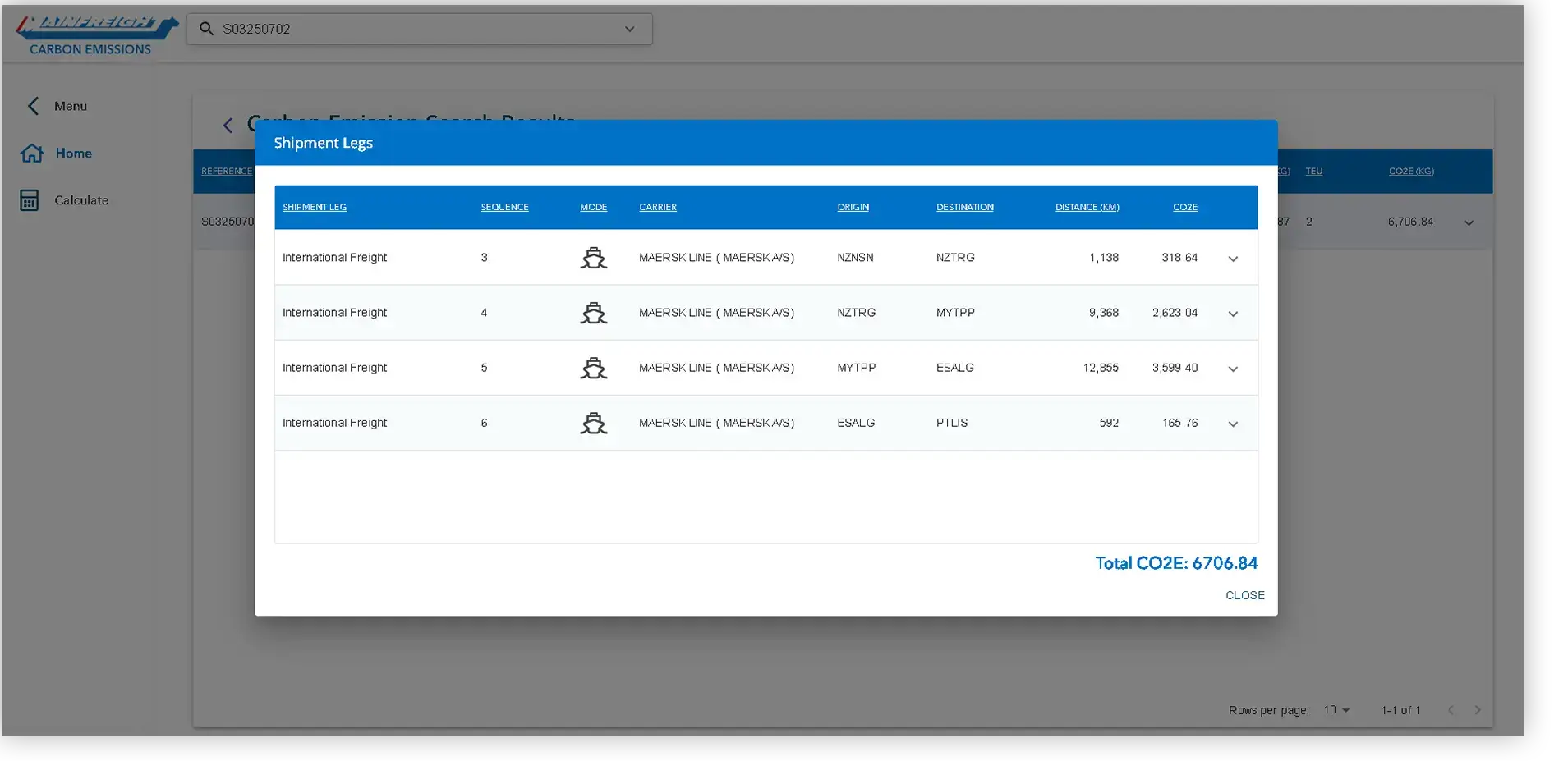

The UI displays each leg of the shipment and its total distance and CO2e.

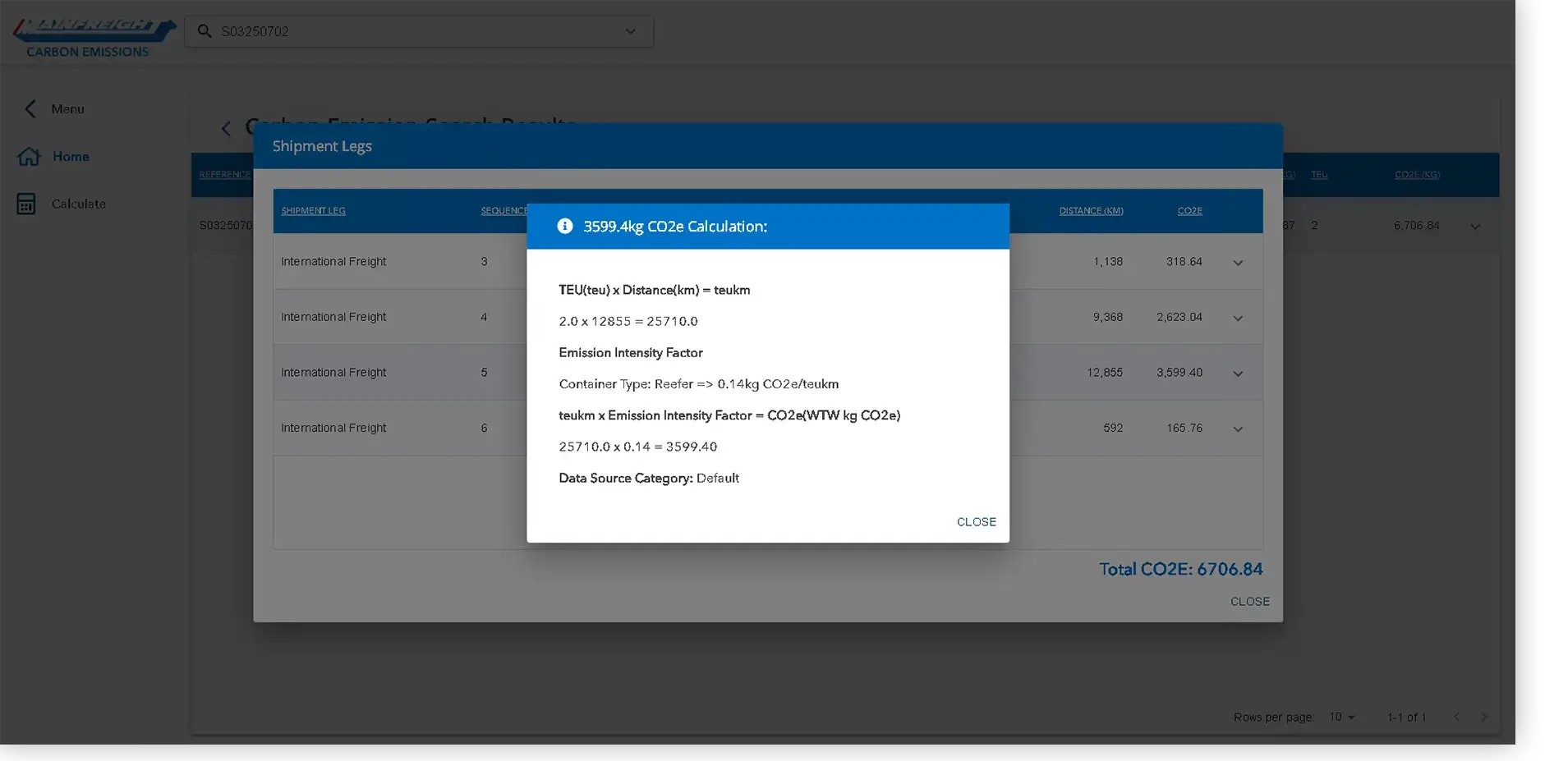

Mainfreight can investigate the calculation method and inputs used to determine the total CO2e for each shipment leg.

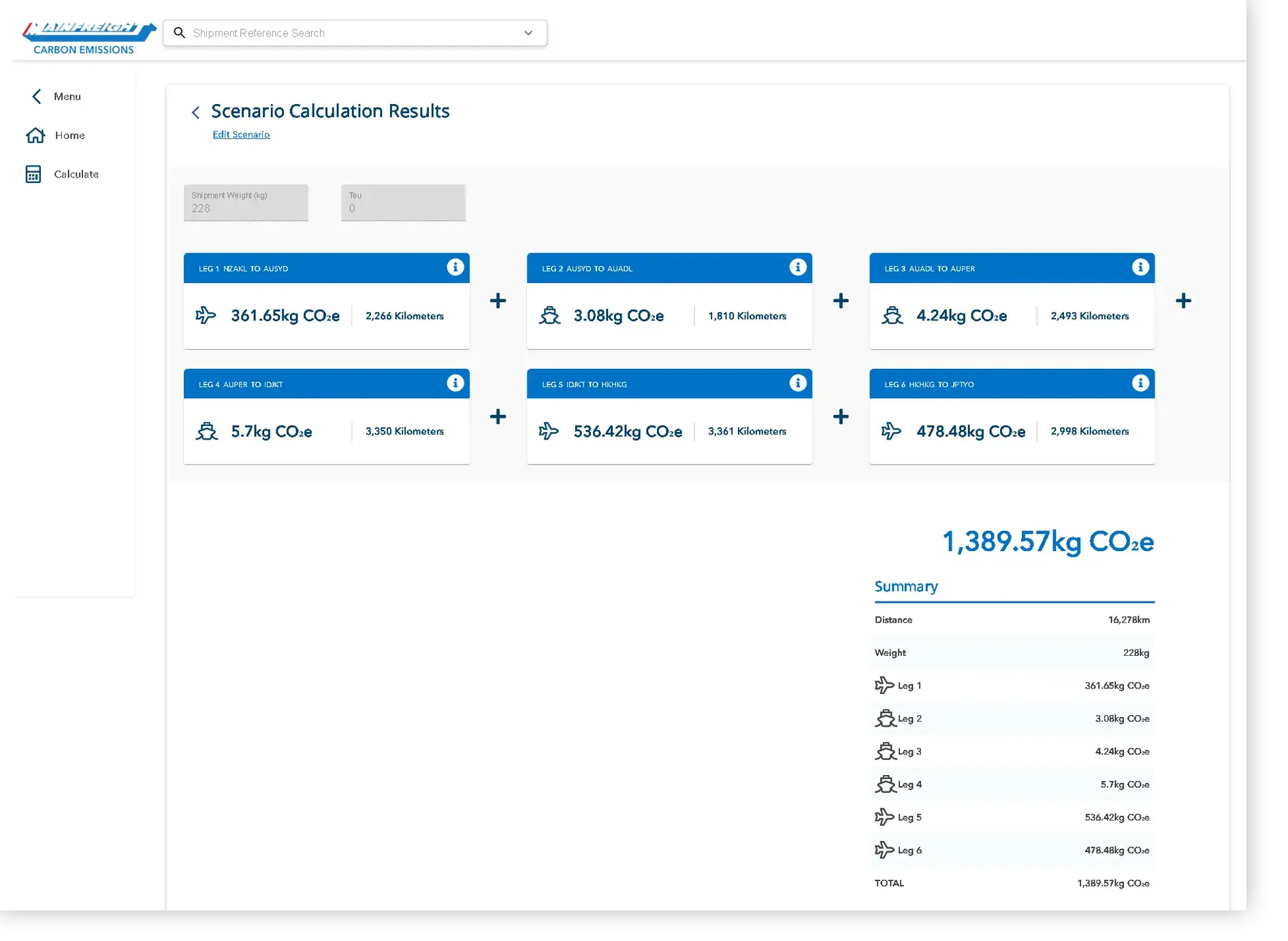

Mainfreight uses the ‘scenario calculator’ to estimate total CO2e for different scenarios within air and ocean shipments.

Success to date

The project has already reached its first significant milestone with the automation of the carbon emissions’ solution in Mainfreight’s system.

In effect, Sandfield has successfully used the GLEC framework and, leveraging API connections and EDI messages, created meaningful data and outcomes specifically for Mainfreight and its clients.

The future state of calculating emissions

The next phase in Mainfreight’s carbon reporting journey involves more focus on estimating variations based on the different modes of transport used. Factors such as the size of truck or ship, trade lanes chosen and the type of fuel used can all create different emission outcomes. The future development will focus on creating more outcomes and the trade-offs associated with each scenario.

The emissions system is already designed to integrate easily with source systems to provide analysis. For example, it could be used to review the carbon result of Mainfreight switching a client's consignment from air to rail in the future. That critical data could then be used to better advise the client on the estimated ETA and the difference in emissions based on the various route options.

Looking even further forward, the possibilities for the system are endless. The system has the potential to provide Mainfreight clients with the ability to select their prefered mode of transport and route, if connected into Mainfreight’s existing client portal, to get an estimate of emissions that would be generated. They could then consider alternative routes and modes of transport and how that could impact cost and the estimated time of arrival versus the amount of emissions produced.